3D printing is one technology that although it is an easily understood concept the potential it has is not understood by most people. If we really think that there will come a time where we will be able to print off almost anything it could change the entire approach to manufacturing. At present, the key issue is the input material as although you can print off almost any shape in the world you need the right input to make any product in the world. A second issue is size. In modern manufacturing, it is taken as a given that when you produce anything it must be smaller than the thing that is producing it. This may be about to change.

Consider any machine that makes something. Whether it is a 3D printer, a mill, or something else it can only produce an item that is smaller than the machine itself. If you then want to create something larger you have to assemble various pieces together. A new development in 3D printing may be about to change this.

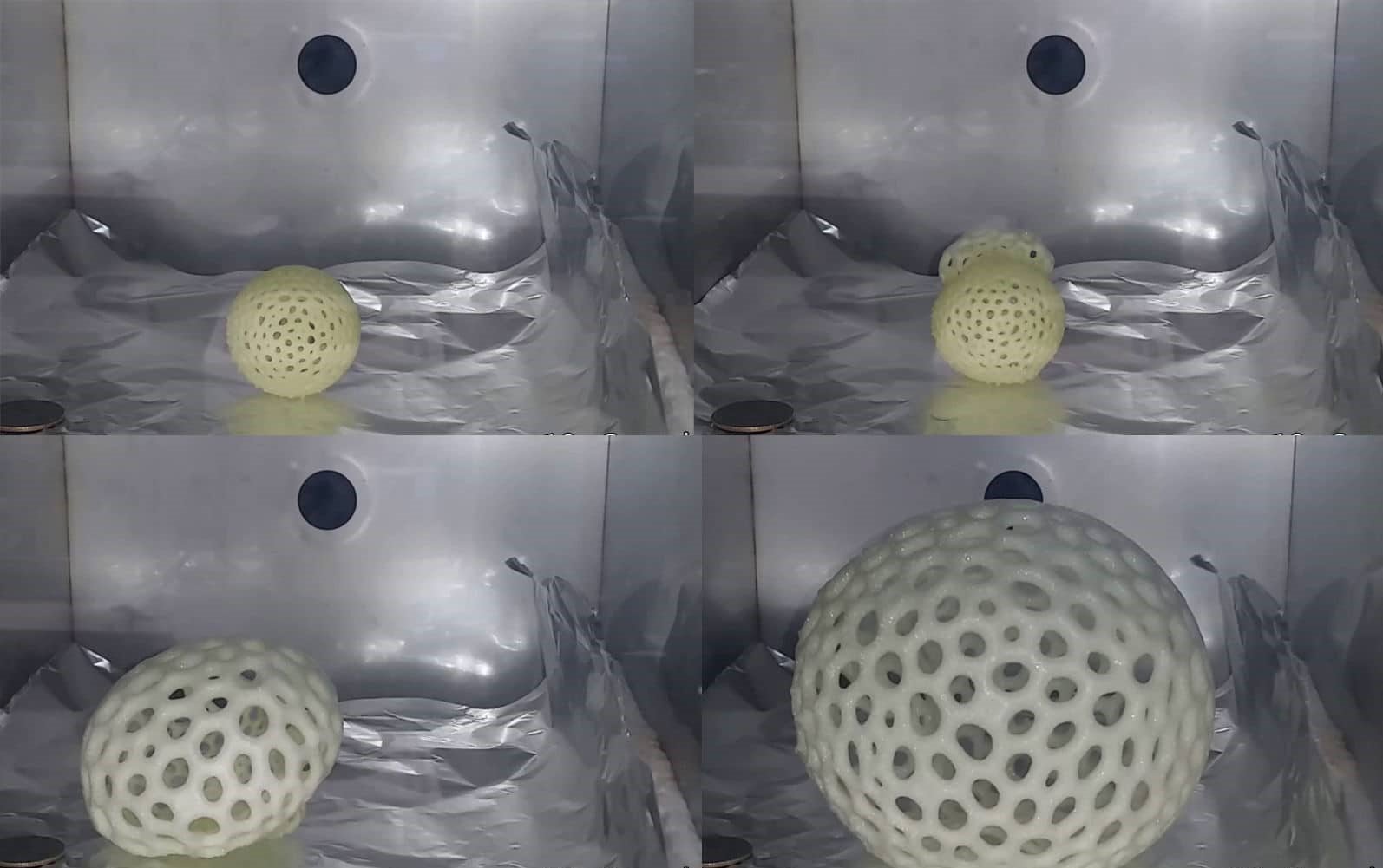

The University College of San Diego had a team of experts looking at 3D printing and the limitation of size. The team successfully printed a foam that once produced could be increased in size by 4000%. On paper, this means that the old manufacturing rule is now out the window, we can start to think about producing things that are bigger than the machine itself.

The team created a prepolymer resin that is basically a hard foam substance. They were able to produce it in standard blocks but also in more complicated shapes. When it expanded it not only kept the original shape but also the complex structure, now just 40 times bigger. The foam was made using two-hydroxyethyl methacrylate, they then paired this methacrylate using a blowing agent. After that, they simply applied considerable heat to the prepolymer for about ten minutes. The 200 degrees celsius heat was the final part of the formula that produced a structure that could increase in size by 40 times.

Of course, we are not going to build many things with foam. Imagine if your car was built from foam, it wouldn’t be too reliable. However, that is missing the point of 3D printing. If 3D printing was responsible for the entire process then yes the foam houses of the future would leave us in a lot of trouble, but if 3D printing is just a part of the process than this approach may be a game-changer. Imagine if we can introduce a new method that can then turn these foam shapes into solid objects, perhaps by covering them with some harder element. This could allow us to build complex shapes at small sizes, grow them to 40 times greater, harden them and use them as we see fit.

Researchers have already identified a number of lightweight applications that the approach could be used for with aerofoils and buoyancy aids two obvious possible solutions. Other industries that they are looking at are architecture, aerospace, energy, and biomedicine. The study has only been published in the last two months so it is still at a very age of discovery. The potential benefits from this idea are massive (40 times bigger than they were before to be exact).

The world is arguably going through the greatest stage of innovation ever. We now have an incredibly intelligent platform of innovation built on the cloud, high-speed internet, the ability to analyze large data sets, and to collaborate across the world. We are researching areas such as 5G, AR, VR, 3D printing, robotics, and AI and they will all produce incredible leaps of capability in the coming years.